Prototype Creation & Reverse Engineering Services

J.K. Pulley Company, Inc. is a provider of a host of prototype manufacturing and reverse engineering services. We are equipped with state-of-the-art equipment capable of precisely reverse engineering parts and accurately producing prototype parts.

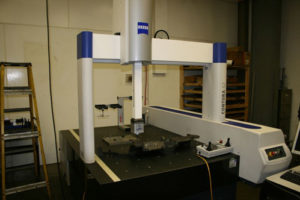

- For our reverse engineering services, we use a high-tech Zeiss Contura G2 AKTIV coordinate measuring machine (CMM) to accurately inspect, measure, and digitize into a CAD model any required part.

- By using our CMM inspection capabilities in conjunction with our CNC turning and machining capabilities, we are able to easily reverse engineer any part.

- We are also equipped to produce prototype parts that strictly conform to customer design requirements and specifications.

- We offer flexibility in our reverse engineering services, such as making design modifications to the reverse engineered part according to client’s requirements.

- We further offer high volume production of the reversed engineered and prototype parts.

Request Quote

Prototype Creation & Reverse Engineering Services Capabilities

| Materials |

- Cast Iron

- Ductile Iron

- Aluminum

- Stainless Steel

|

- Steel and Alloy Steel

- Bronze

- Brass

- Titanium

|

- Magnesium

- Weldments

- Plastic

|

| Equipment |

- Zeiss Contura G2 AKTIV

- Travel: 700 x 700 x 600 mm

- Minimum Tip Diameter: 0.5 mm

- Measuring Tolerance: 0.071 + L/300

- (L is Measured Length in Inches)

- 4-Axis Okuma MH500 Horizontal Mill

- Okuma MH800 Horizontal Mill with Rotary Indexer

- Okuma MCV60 Vertical Mill 30 x 60 x 27 inches Travel

- Okuma MX45 Vertical Mill 15 x 30 x 17 inches Travel

- Cincinnati Saber 1000 Mill 20 x 40 x 17 inches Travel

- Blanchard Grinder 36 inches maximum diameter

- 4-Axis Okuma LU45 CNC Lathe

- Maximum Swing: 32 inches Diameter

- Maximum Turning Length: 36 inches

- 2-Axis Okuma LB35 CNC Lathe

- Maximum Swing: 18 inches Diameter

- Maximum Turning Length: 36 inches

- 6 – 4-Axis Okuma LU15 Standard Chucking Lathes

- Maximum Swing: 14 inches diameter

- Okamoto Surface Grinder 12 x 24 inches Table

- Vertical and Horizontal Sunnen Honing Machine

- Pfauter Gear Hobber with Maximum Diameter 14 inches

- Pioneer and Oil Gear Broaching Machines

- Robotic Cell #1:

4 Axis LU15 Lathe

Okuma Captain Lathe

Motoman Robot

Load and Unload Conveyors

- Robotic Cell #2:

Lu15 4 Axis Lathe

Okuma Captain Lathe

Motoman Robot

Kira Drill and Tap Station

Load and Unload Conveyor

- Robotic Cell #3:

LU300 Lathe

Drill and Tap Station

Ty Miles Broaching Machine

Load and Unload Conveyors

|

| Software Used |

Calypso CAD |

| Capabilities |

- Custom Made Pulleys

- CNC Milling

- CNC Turning

- Gear Hobbing

|

- High Production Robotic Machining

- Reverse Engineering / Prototype Creation

- Welding Services

- CMM Inspection

|

More Information

| Quality Certification |

ISO 9001:2015 |

| Additional Features |

Design assistance |